|

ステンレス鋼配管の健全性評価に関する研究 |

|

|

原子力発電所や化学プラントでは100kmを超えるステンレス鋼製配管が用いられている.

利用年数に伴いき裂や腐食で損傷したりする経年劣化が生じるため,

長期間利用するためには経年劣化が生じた配管の交換が必要になる.

原子力発電所の配管の維持においては,発電用原子力設備規格維持規格が設けられており,

維持規格に則って配管の健全性評価が行われ,必要に応じて配管の補修交換が行われている.

|

|

F.Y.2016 |

|

Nuclear power plants have many piping. The crack on the piping causes a serious accident of a nuclear power plant. Integrity of aging piping should be assessed for safety operation of the nuclear power plant. In this study, following three topics are investigated: (1) Stress ? displacement curve of a single notched specimen is compared with that of a multiple notched specimen before notch penetration, (2) Stress ? displacement curve of a single notched specimen is compared with that of a multiple notched specimen after notch penetration and (3) Plastic collapse stress and maximum stress of a multiple notched specimen are estimated by those of a single notched specimen. Conclusions are as follows: (1) The stress - displacement curve of a multiple notched specimen matches that of a single notched specimen before notch penetration, (2) The stress - displacement curve of a multiple notched specimen matches that of single notched specimen after notch penetration and (3) Plastic collapse stress and maximum stress of a multiple notched specimen can be estimated by those of a single notched specimen. ↑ Return to top |

|

F.Y.2015 |

|

Deterioration of old nuclear power plants is a significant problem to operate the safely. Multiple cracks might be detected on stainless steel piping used for the plants. Integrity evaluation of cracked piping is important to operate the plants safely and reasonably. The aims of this study are to establish an integrity evaluation method of the cracked stainless steel pipe and clarify the following points: (1) To provide simplified evaluation of the multiple cracked stainless steel pipe, (2) The load histories effects plastic collapse of the piping with multiple cracks and (3) To Propose of evaluation formula to the maximum stress. Conclusions are as follows: (1) Multiple cracks on stainless steel piping can do handling a single crack, (2) The load histories do the plastic collapse strength and (3) The maximum stress can be estimated using the proposed evaluation formula. ↑ Return to top |

|

F.Y.2014 |

|

Aging of nuclear power plants in Japan is a significant problem for operating the old plants safely. Many stainless steel piping are used in the nuclear power plants. Cracks are identified on the stainless steel piping used for the old plants. One of the integrity evaluation is LBB(Leak before break) concept. LBB concept of cracked piping is important for operating the old plants safety and reasonably. The aim of the study are to establish the integrity evaluation method of the cracked stainless steel pipe and clarify the following points:(1)The effect of the load history on the crack opening displacement, (2)Whether to satisfy LBB concept on the combined load, (3)The availability of evaluation formula to the maximum stress . Conclusions are as follows:(1)The load histories affect the crack opening displacement. (2)LBB concept is satisfied on the combined load. (3)The maximum stress can be estimated using the developed evaluation formula. |

|

F.Y.2013 |

|

Aging nuclear power plants in the world is a significant problem to operate the old plants safely. Multiple cracks are identified on the stainless steel piping used for the old plants. The integrity evaluation of cracked piping is important to operate the old plants safely and reasonably. The aims of this study are to establish the integrity evaluation method of the cracked stainless steel pipe and clarify the following points: (1) The effect of the multiple cracks on the plastic collapse strength, (2) The effect of the load histories on the plastic collapse, (3) The availability of evaluation formula to the maximum stress. Conclusions are as follows: (1) The multiple cracks in stainless steel piping can be considered to be equivalent to a single crack in the integrity evaluation. (2) The load histories do not affect the plastic collapse. (3) The maximum stress cane estimated using our evaluation formula. ↑ Return to top |

|

F.Y.2012 |

|

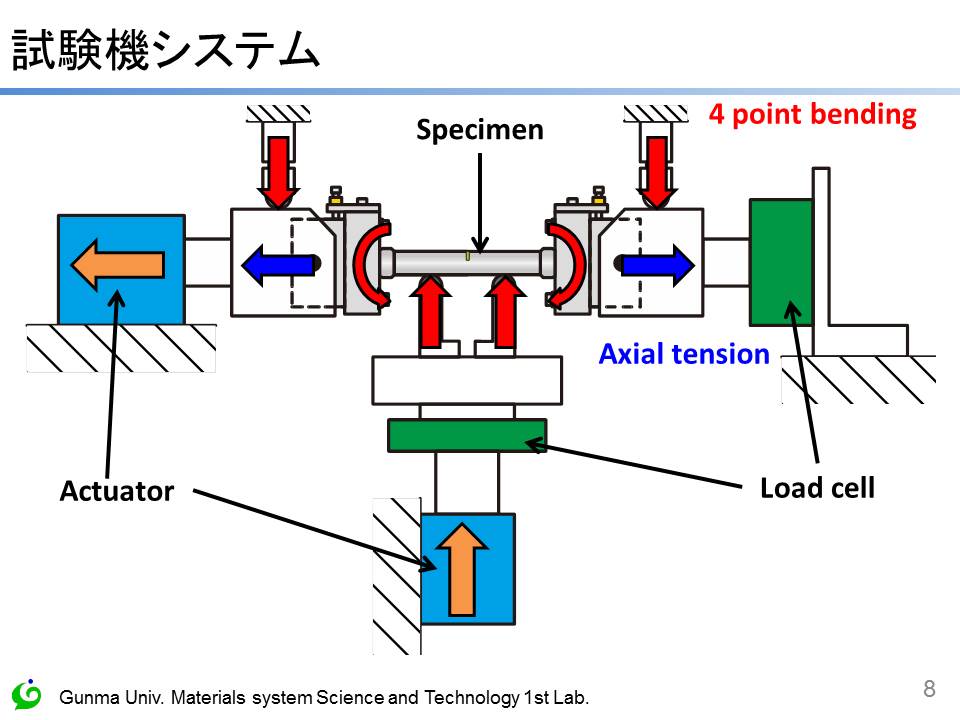

Aging of nuclear power plants in Japan and abroad has become a problem. Many stainless steel piping are used in nuclear power plants. Multiple flaws have been identified on the pipe by the effect of aging. It is important to evaluate the strength of the pipe with multiple flaws. The aim of this study is to investigate on the effect of multiple flaws on the plastic collapse strength of the stainless steel piping and simplify the multiple flaws shape of stainless steel piping subjected to axial tension and bending. In addition, we studied usefulness of the evaluation method by the maximum load. Conclusions are as follows: (1) It was clarified that the plastic collapse strength of stainless steel pipe with multiple notches can be evaluated safely using the theoretical plastic collapse strength of the elastic perfectly plastic pipe with the single notch. (2) Evaluation method by the maximum load may be applied in carbon steel piping of the actual dimensions. ↑ Return to top |