|

傾斜機能耐熱材料の創製と高温強度評価に関する研究 |

|

|

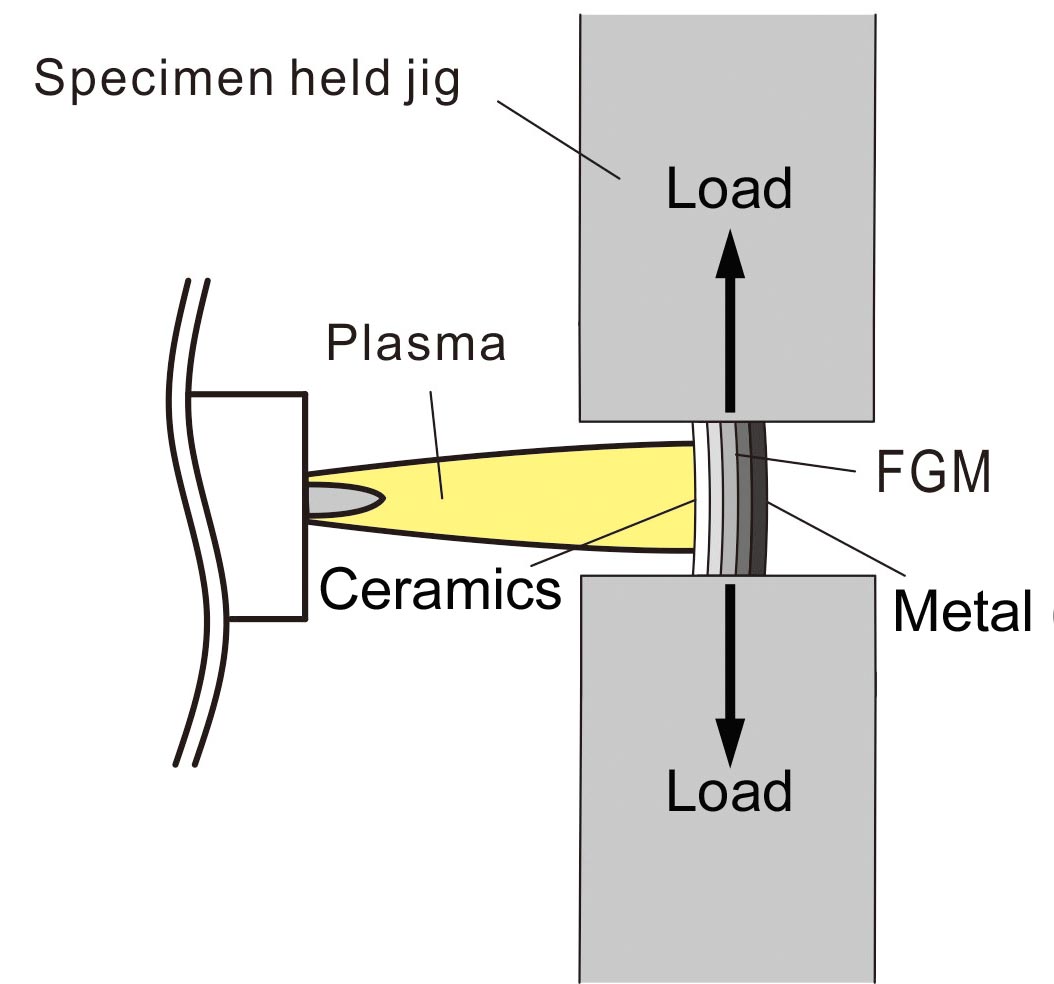

宇宙から地球に戻る際,宇宙往還機は約2000Kの超高温にさらされる.このため,スペースシャトル(すでに退役している)のような宇宙往還機の構造の表面には優れた耐熱材料を必要とする.このような場合,金属の表面にセラミックスをコーティングした材料を用いる.金属は温度の上昇に伴い熱膨張するが,セラミックスはほとんど膨張しないため,金属とセラミックスの間で発生する大きな熱応力が破壊の原因になる.本研究室ではこの応力を緩和可能な耐熱傾斜材料の開発を行っている.傾斜機能材料は材料の組成を内部で傾斜的に変化させた材料である.金属100%から徐々にセラミックスの配合割合が多くなりセラミックス100%になるような傾斜機能材料であれば大きな熱膨張の発生を抑制できる.本研究室ではこのような構造を持つ傾斜機能材料を開発し,プラズマフリージェット用いることで超高温下における傾斜機能材料の強度を評価している. |

|

F.Y.2016 |

|

Thermal stress due to the difference of the thermal expansion coefficient between a metal and a ceramics is relaxed by the graded composition of functionally graded materials (FGMs) with a metal/ceramics system. However, the defects such as warping and delamination occur in the FGMs manufactured by powder molding method. The purposes of this study are to investigate the effects of graded content of binder and solvent extraction on the generation of defects in 9-layer Ni/ZrO2 FGMs in order to manufacture the FGMs without the defects. Plasma creep rupture test of the FGMs is carried out at about 1500 K. The upper limit of continuous irradiation time of air plasma free jets is 120 seconds. Conclusions of this study are as follows; 1) Warping of FGMs is almost prevented by graded addition of a binder to mixture of Ni and ZrO2 powders and placement of the weight on the compact during sintering. 2) Cracks occur on the Ni-0 surface during solvent extraction. The binder composition should be discussed to prevent to occur cracks on the Ni-0 surface. 3) The long term creep rupture life of FGMs can be estimated using short term creep rupture life and Larson-Miller Parameter. ↑ Return to top |

|

F.Y.2015 |

|

Multi-layered Ni/ZrO2 functionally graded materials, FGMs are manufactured by powder molding. Flaw occurs in FGMs with thermal stress in manufacturing. For preventing flaw in 9-layered FGMs, a part of binder is removed with solvent extraction. The solvent extraction prevents flaw in FGMs during heat degreasing. The extraction ratio is high when hydrocarbon is used as solvent extraction. Delamination occurs at the end of FGMs. For preventing delamination in FGMs, higher load is needed in manufacturing a laminated compact. Five-layered FGMs with composition distribution parameter n=0.59 are manufactured. Delamination occurs at the Ni-0 layer. Thinner Ni-0 layer would prevent delamination. A plasma creep rupture test provides the stress-rupture time diagram. It is possible to predict creep rupture life under low applied stress condition with Larson-Miller Parameter, LMP. ↑ Return to top |

|

F.Y.2014 |

|

Multilayered Ni/ZrO2 functionally graded materials (FGMs) were developed with a powder molding. Thermal stress makes flaws occur. For flaws free FGMs, we manufactured FGM with extraction for wax in the binder. The extraction is keeping the shape during debinding. We used N-methylpyrrolidone (NMP)for solution. Extraction ratio was 8~15 %. Specimens with extraction occured defects in sintering. Defects are due to exfoliation of compact in extraction and difference extraction ratio in each layer. Vickers hardness of FGM with extraction is lower than FGM without extraction. Holes would occur FGM with extraction during thermal debinding process. It is impossible to apply extraction with use of NMP to FGM in this study. In Ni/ZrO2 FGMs without extraction, it becomes possible to estimate creep rupture lifetime. ↑ Return to top |

|

F.Y.2013 |

|

Multilayered Ni/ZrO2 functionally graded materials (FGMs) was developed with a powder injection molding. Thermal stress makes flaws occur. For flaws free FGMs, We calculated binder gradient composition which thermal stress in FGMs is zero at maximum sintering temperature. The defective state different by various binder gradient composition. By setting binder composition appropriately, it is possible to control thermal stress. For appropriate binder gradient composition, it is necessary to take into account the temperature dependence of the coefficient of thermal expansion. For result of heat resistance test, it has become possible to estimate the plasma irradiation area temperature. In Ni/ZrO2 FGMs, transient creep and steady creep were confirmed but tertiary creep was not. Because stress-creep rupture time diagram was obtained, it becomes possible to estimate creep rupture lifetime. ↑ Return to top |

|

F.Y.2012 |

|

Functionally gradient material,FGM is an attractive structural material for a space plane. In the research, FGM is composed of Ni and ZrO2. Ni-ZrO2 FGM composition is changed from Ni to ZrO2 gradually in one material. FGM was manufactured by powder molding method as its curvature and delamination reduces. Vickers hardness test,microstructure observation, density measurement, plasma test and creep test were carried out. The following results were obtained from the tests. By making a molded compact having a curvature, a warp of FGM has been reduced. The mechanical properties of FGM have been improved by increasing the maximum temperature during the sintering. The creep rupture strength of Ni-ZrO2 FGM was strongly dependent on the presence of cracks or delamination. ↑ Return to top |